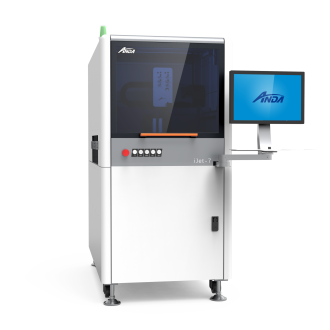

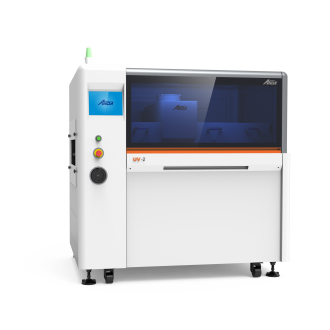

About Anda

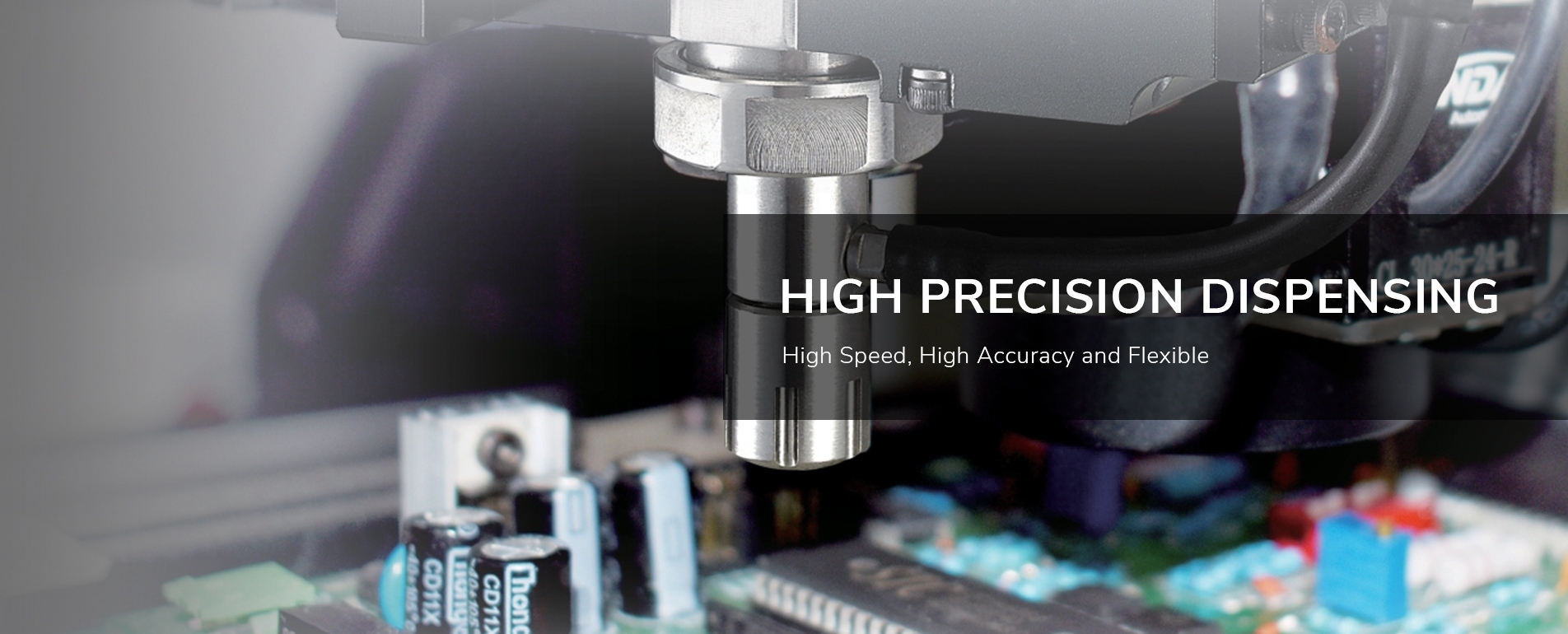

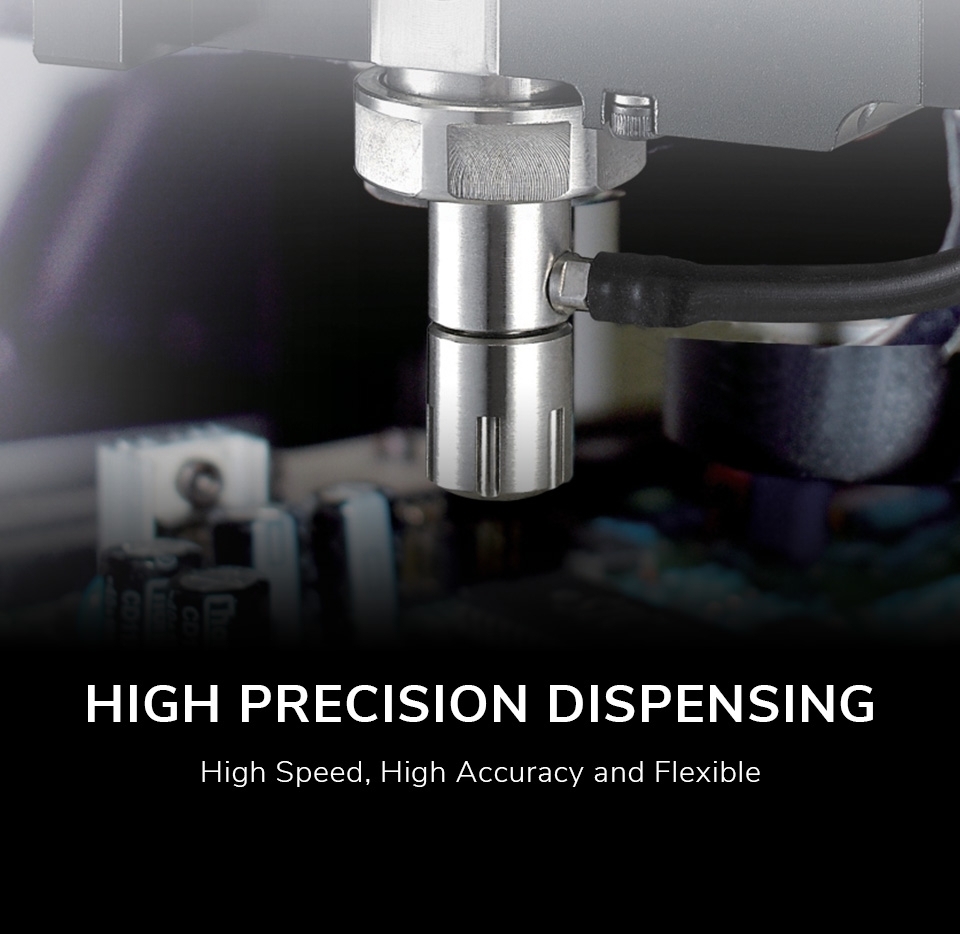

Anda Automation is one of the most innovative company to develop fluid application and custom design manufacturing equipment. We mainly develop high precision dispensing/coating valve, linear motor, servo linear guide, polymer mineral casting and optical assembly equipment.